Understanding the conductivity meter cost in 2026 is essential for businesses and researchers alike. The cost varies significantly depending on brand, specifications, and features. Some meters are simple, while others are equipped with advanced technology for precise readings.

In the coming years, expect new factors to influence prices. Trends in manufacturing and advancements in materials may drive costs up or down. A basic model might cost a few hundred dollars, but high-end devices could reach thousands. The market will be competitive, and prices will fluctuate.

Choosing the right conductivity meter involves more than just cost. Accuracy, durability, and support services are also critical. Investing in a reliable meter can save money long-term. Reflecting on the balance between cost and quality is vital for achieving good results.

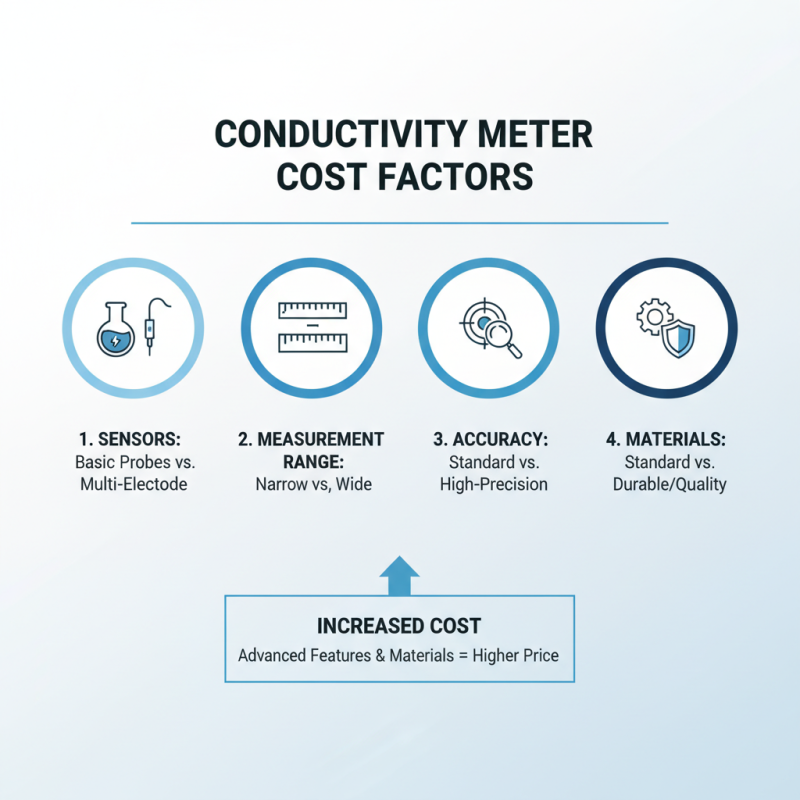

When calculating the cost of a conductivity meter in 2026, several factors come into play. Material quality is vital. Meters made from high-grade components can cost more but often last longer. According to industry reports, nearly 25% of users cite durability as a crucial factor affecting their choice. Additionally, features like data storage and connectivity can significantly impact pricing. A multi-function meter might cost 30% more than a basic model.

Another important aspect is the calibration requirements. Meters that require frequent adjustments can incur hidden costs. Calibration can add up to 15% of the initial price over time. It's essential to consider the long-term implications when evaluating the price.

Tips: Always compare specifications when shopping. Do not hesitate to ask for detailed reports from suppliers. Consider the environment in which the meter will be used; extreme conditions can lead to premature failure. Therefore, investing in a robust unit can save money in the long run. Make informed decisions to avoid regret later. Remember, the cheapest option may not be the best in the end.

Conductivity meters are essential tools for measuring the conductivity of liquids. Their cost can vary based on several components and features. Key factors include the type of sensors used, the measurement range, and the level of accuracy required. Basic meters may have simple probes, while advanced ones feature multi-electrode configurations. The quality of materials can also impact prices. High-quality components tend to enhance durability, but they come at a premium.

Another aspect to consider is display technology. Some meters use simple LED screens, while others have high-resolution displays that provide detailed readouts. Data logging capabilities are also important. Meters that can store data or connect to software for analysis often cost more. Additionally, features like temperature compensation can drive up prices. Users must assess their needs when selecting a meter.

It's interesting to note that not all features may be necessary for every user. For instance, a simple lab application might not require advanced data logging. Hence, understanding personal or organizational requirements is crucial to calculating the best investment in a conductivity meter. The interplay of these components plays a significant role in determining overall costs. Proceed carefully.

In 2026, calculating the cost of a conductivity meter requires careful comparison of various brands and models. The market is diverse, with prices ranging from $100 to over $1,500. Basic models often lack advanced features, while high-end devices offer precision and added functionalities. Not all expensive meters provide proportional performance. Consumers may find themselves evaluating quality versus cost.

Reports from industry analysts indicate that user-friendly interfaces in meters often drive up their price. In some models, additional features such as data logging and Bluetooth connectivity can be appealing. Yet, these options may not be necessary for every application. A functionality-focused assessment might reveal that simpler meters suffice for routine testing.

Despite the wide array of choices, several buyers express confusion over pricing. A significant portion feels uncertain about the actual value of advanced features. Surveys suggest many users prioritize basic functionality over extra capabilities. Choosing the right device often requires a reflection on both budget and actual needs. It's easy to get caught in the allure of high-priced gadgets, forgetting that the simplest solution may often be the most effective.

In 2026, the conductivity meter market is expected to face significant changes. Advances in technology could lead to new features and improved accuracy. This might increase production costs. However, innovation can also create more affordable options, impacting overall pricing in the market.

Demand will likely rise due to environmental regulations and industrial needs. Industries focused on water quality will drive this demand. This could lead to price fluctuations. Moreover, supply chain issues may add to unpredictability in costs. Manufacturers might need to adapt quickly to remain competitive.

As consumers look for more detailed analysis and real-time data, the market may shift. Some companies might struggle to keep up. New entrants could challenge established players, leading to price wars. The balance between quality and cost will be crucial for buyers and sellers alike.

| Year | Average Price (USD) | Market Growth Rate (%) | Key Factors Influencing Price |

|---|---|---|---|

| 2023 | $150 | 5% | Technological Advancements, Supply Chain Issues |

| 2024 | $158 | 6% | Increased Demand, Market Competitiveness |

| 2025 | $167 | 7% | Raw Material Costs, Technology Integration |

| 2026 | $175 | 8% | Regulatory Changes, Production Efficiency |

Calculating the cost of a conductivity meter in 2026 requires looking at the Total Cost of Ownership (TCO). TCO goes beyond the initial purchase price. It includes maintenance, operation, and training costs. Consider the longevity of your meter. A cheaper model may cost more in repairs over time.

When you evaluate TCO, think about energy consumption. An efficient meter can save money in operations. Over a year, these savings can add up significantly. Don't ignore the cost of calibration as well. Regular calibration ensures accuracy but isn't always factored in.

Tips: Explore whether remote monitoring features can add value. They may help reduce the need for physical checks. Evaluate your team's ability to operate the device. If training is needed, include those costs. Always reflect on potential hidden expenses. Letting small details slip can lead to larger issues later on.