In the realm of analytical chemistry, precision is a non-negotiable standard, particularly when it comes to measuring substances like hydrogen peroxide. To ensure accurate results, professionals rely heavily on specialized instruments such as the hydrogen peroxide test meter. Dr. Emily Richter, a leading expert in chemical analysis, emphasizes the need for precise measurement tools: "Inaccurate readings can compromise not only the outcome of experiments but also safety and compliance in various industries."

The significance of using a hydrogen peroxide test meter extends beyond mere accuracy; it plays a crucial role in applications ranging from food safety to environmental monitoring. As industries increasingly recognize the value of comprehensive testing for hydrogen peroxide levels, the demand for reliable measurement instruments continues to rise. This makes understanding the capabilities and benefits of a hydrogen peroxide test meter essential for professionals seeking to enhance their operational standards.

In conclusion, implementing a high-quality hydrogen peroxide test meter can provide the reliability needed for critical applications, ensuring that measurements reflect true concentrations. As Dr. Richter aptly points out, investing in accurate testing technology is not just about improving data quality—it's also about fostering a culture of safety and responsibility within any organization handling this powerful compound.

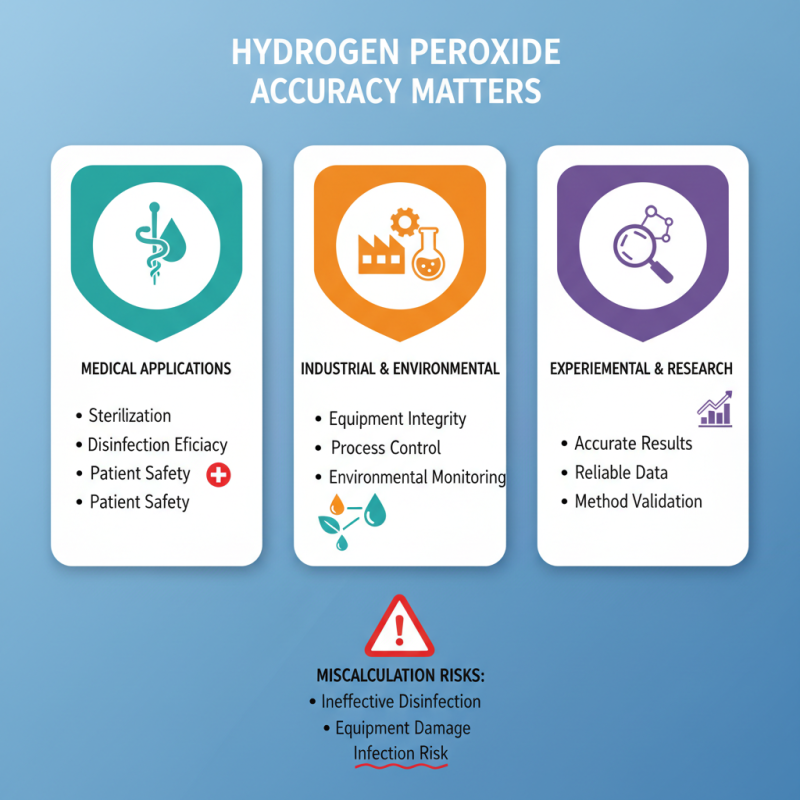

Accurate measurement of hydrogen peroxide is crucial in various applications, including medical, industrial, and environmental contexts. Miscalculating the concentration of this compound can lead to ineffective disinfection, potential harm to equipment, and inaccurate experimental results. For instance, in healthcare settings where hydrogen peroxide is used for sterilization, even a small deviation from the intended concentration might compromise safety and efficacy, increasing the risk of infection in vulnerable populations.

A dedicated hydrogen peroxide test meter provides precise readings, enabling users to monitor this chemical's levels effectively. This tool supports adherence to safety regulations and operational guidelines, ensuring that large-scale applications such as wastewater treatment and food processing remain compliant with hygiene standards. In laboratories, accurate hydrogen peroxide measurements can influence experimental outcomes, making it essential for researchers to rely on calibrated instruments. Thus, incorporating a reliable test meter into routines not only enhances safety but also fosters trust in the results derived from hydrogen peroxide usage across various sectors.

Hydrogen peroxide test meters are essential tools for ensuring accurate measurements of hydrogen peroxide in various applications, from industrial processes to medical environments. These meters use advanced sensor technology to quantify the concentration of hydrogen peroxide in a sample, providing real-time data that is crucial for monitoring and quality control. According to a report from the International Journal of Environmental Research, precise measurement of hydrogen peroxide levels is vital for compliance with safety regulations, as improper concentrations can lead to ineffective disinfection or hazardous conditions.

Understanding the functionality of these test meters can significantly enhance operational efficiency. Most modern hydrogen peroxide meters leverage photometric analysis or electrochemical sensing methods to detect the compound's presence in a solution. A study published in the Journal of Food Science highlights that the usage of these meters can reduce testing errors by up to 30%, thereby improving the overall reliability of the testing process. Furthermore, the portability and ease of use of these devices allow for on-site testing, which streamlines workflows and minimizes the risk of contamination that can occur with traditional lab testing methods. By employing accurate test meters, companies can ensure optimal performance in applications that rely on hydrogen peroxide, guaranteeing safety and effectiveness in their processes.

When selecting a hydrogen peroxide test meter, there are several key features that are essential for ensuring accurate and reliable measurements. One of the most critical aspects is the device's sensitivity and range. According to a report by the International Society for Food Safety, effective monitoring of hydrogen peroxide levels is crucial, especially in food processing and sanitation practices. Test meters that provide a detection range from 0.01% to 30% are ideal, as they can accommodate a variety of applications, from cleaning to disinfection.

Another important feature to consider is the meter's calibration standards. Regular calibration is necessary for consistent accuracy over time. A comprehensive study published in the Journal of Environmental Monitoring states that meters calibrated to recognized standards improve measurement reliability by up to 40%. Additionally, features such as data logging capabilities and easy-to-read displays can enhance usability in field conditions, allowing users to track changes and trends in hydrogen peroxide concentrations effectively. With the growing emphasis on hygiene and safety across various industries, investing in a high-quality hydrogen peroxide test meter equipped with these features is more important than ever.

Hydrogen peroxide test meters are essential tools with a wide range of applications across various industries. They provide precise measurements that are critical in settings such as healthcare, food processing, and water treatment. In healthcare, for instance, ensuring the correct concentration of hydrogen peroxide is vital for effective disinfection and sterilization processes. Accurate readings help professionals maintain safety standards and prevent contamination, making the use of test meters indispensable.

In the food processing industry, the application of hydrogen peroxide is common for sanitization purposes. Using test meters ensures that the concentration is neither too low, which may fail to eliminate pathogens, nor too high, which may pose risks to food safety. Furthermore, in water treatment facilities, monitoring hydrogen peroxide levels is crucial for effective oxidation and disinfection processes, ultimately ensuring clean and safe water for community consumption.

Tips: When using hydrogen peroxide test meters, always calibrate them regularly to ensure accurate readings. Additionally, familiarize yourself with the specific operating ranges and methodologies of the meter to maximize effectiveness. Finally, consider maintaining a log of readings for historical reference, which can be beneficial for trend analysis and compliance with safety regulations.

| Application | Importance | Benefits |

|---|---|---|

| Food Processing | Ensures food safety by monitoring sterilization processes. | Reduces contamination risk and improves product shelf life. |

| Water Treatment | Monitors hydrogen peroxide levels for effective disinfection. | Ensures compliance with health regulations and enhances water quality. |

| Healthcare Disinfectants | Validates disinfection protocols in clinical settings. | Enhances patient safety and minimizes infection rates. |

| Industrial Cleaning | Ensures correct concentration for effective cleaning solutions. | Improves efficacy of cleaning products and worker safety. |

| Agriculture | Monitors levels for pest control and crop disease management. | Enhances crop yield and reduces chemical overuse. |

Maintaining accurate measurements in hydrogen peroxide testing is crucial for various applications, from environmental monitoring to laboratory research. Proper calibration of your hydrogen peroxide test meter ensures that you obtain reliable and consistent results. According to a report by the Environmental Protection Agency (EPA), inaccurate measurements can lead to significant discrepancies in data interpretation, potentially impacting decision-making processes in water treatment and sanitation. Calibrating your meter at regular intervals, preferably before each use, can help mitigate these risks. Always use standard solutions or certified reference materials relevant to your specific measurement range during calibration for optimal accuracy.

In addition to calibration, routine maintenance of your test meter is essential to preserve its functionality and accuracy. Regular cleaning of the sensor and inspection of all connections can prevent data distortion and equipment failure. Research published in the Journal of Environmental Monitoring suggests that neglecting maintenance can result in up to a 20% decrease in measurement accuracy over time. Users should follow the manufacturer's guidelines for both calibration and maintenance and incorporate these practices into routine operational protocols to ensure high standards of accuracy and reliability in hydrogen peroxide testing.