Are You Ready for Remote Equipment Monitoring?

Are you ready for remote equipment monitoring to boost efficiency and reliability in water treatment? Imagine getting an alert before a pump fails — not after. Instead of rushing to a site hours away, you already know which valve needs attention and what part to bring. That’s the power of remote equipment monitoring: fewer surprises, faster fixes, and complete confidence in your system’s performance.

Why Remote Equipment Monitoring?

In today’s fast-paced, data-driven world, water treatment professionals face growing pressure to increase efficiency, reduce risk, and maintain compliance. If you’re still relying on clipboards, spreadsheets, or scheduled site visits to monitor critical system parameters, you’re not alone. But, you may be missing out on significant advantages that remote equipment monitoring can offer.

What Is Remote Monitoring & What Can It Do for You?

Remote equipment monitoring connects your on-site devices — such as pumps, sensors, and controllers — to the cloud through a secure modem or gateway. Each device continuously collects data on flow, pressure, chemical levels, and system performance. That data is then transmitted to a centralized platform, where it’s analyzed and displayed on an intuitive dashboard.

Engineers and operators can log in from any location to view live readings, check historical trends, and receive alerts when parameters drift out of range. This connected approach transforms raw data into actionable insights. This gives you the ability to make decisions based on facts, not guesswork.

Remote equipment monitoring is the use of technology to capture equipment performance data from a distance. It uses sensors, controllers, routers, modems, and other system components as well as data analysis tools.

This technology enables:

Real-time system visibility: 24/7 monitoring, diagnostics, and instant status updates. You don’t have to be on-site to see what’s going on; you’ll always have a unified system view and real-time performance insights to optimize your operations.

- Predictive maintenance: Advanced diagnostics and continuous oversight allow you to catch anomalies or deteriorating performance early, before they turn into failures or downtime.

- Automated compliance reporting: Some solutions, like Flight, automatically log and store system data, making it easier to generate detailed reports and maintain accurate records for audits and compliance reviews, all without manual data collection.

- Cost savings: By reducing the need for frequent site visits and manual inspections, remote equipment monitoring helps lower operational expenses. Remote access and automated alerts save both time and travel costs.

Remote equipment monitoring solutions like Flight by AquaPhoenix give you real-time visibility into your systems, without needing to be on site. That’s because Flight includes three of the most crucial system components that you need to capture data and ensure reliable access to it 24/7/365: hardware (modem), data plan (connectivity), and support (proactive, live modem uptime monitoring by trained professionals).

Controllers capture essential data. Flight makes sure you see it.

The Flight modem is designed for reliability and flexibility in the field. It securely collects data from controllers, sensors, and tanks, then transmits it to the cloud using a robust, industrial-grade connection. Whether your site relies on cellular or satellite communication, Flight ensures your data is accessible anytime and anywhere. Built to handle demanding environments, it operates continuously in a variety of conditions. This ensures uninterrupted monitoring even in remote or hard-to-reach locations.

These platforms deliver automated alerts, historical data, and actionable insights that empower your team to act faster, smarter, and with greater confidence. But before you dive in, it’s important to evaluate your organization’s readiness for this digital transformation.

Ready to Take Flight?

Transitioning to remote monitoring is more than a technology upgrade; it’s a shift toward smarter, more efficient operations. With the Flight modem, you gain the tools to monitor critical systems in real time, reduce maintenance costs, and peace of mind knowing your equipment is always connected.

Taking the first step doesn’t require a full system overhaul — it starts with understanding where you stand today. Our free readiness checklist helps you identify gaps in connectivity, data access, and process visibility. Whether you operate one site or many, this simple self-assessment will show you how close you are to achieving continuous insight into your water treatment systems.

Don’t wait for the next unexpected outage — get ahead of it. Download the checklist and start building your connected operation today.

Our easy-to-use readiness checklist covers aspects such as data collection and system infrastructure, team readiness and organizational culture. Companies in the early stages of digital transformation lean on experts, such as the Flight team at AquaPhoenix to help determine next steps. Our checklist can help you identify gaps that need to be addressed as you prepare to transform from manual to digital. Understanding where you are is just as important as creating an actionable plan that gets you to the next stage of growth.

Want to know if your facility is ready to make the move? Flight Readiness Checklist to evaluate your current setup and take the first step toward seamless remote monitoring.

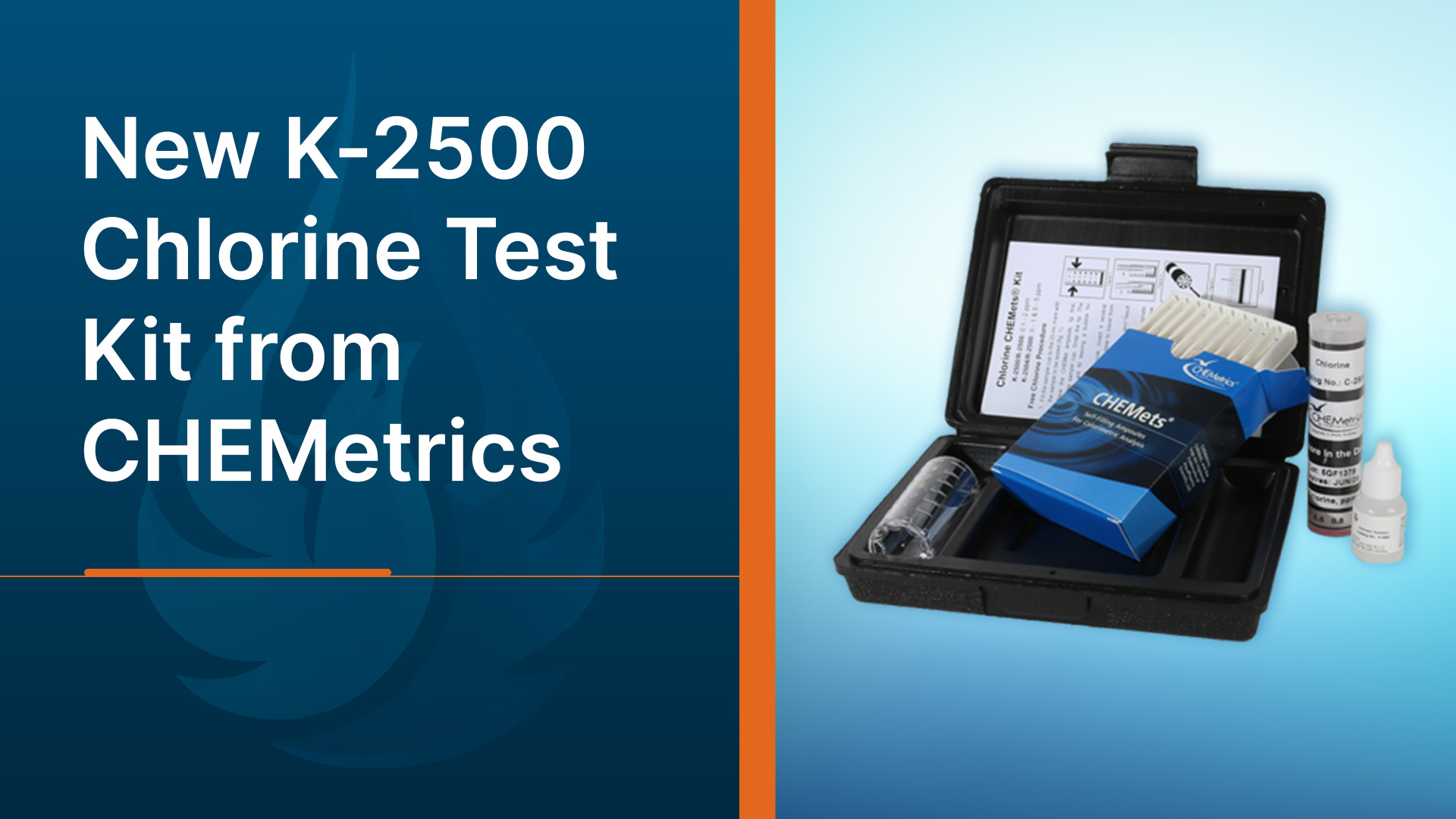

We’re excited to introduce the CHEMetrics K-2500 Free and Total Chlorine Test Kit! This low-range test kit is designed to make chlorine testing simple, accurate, and affordable for anyone who needs to monitor water quality at lower concentrations. With a range of 0.1–2 ppm and increments of 0.2 ppm, it’s a perfect fit for applications where precision at the low end really matters.

Packed in a durable plastic case, each kit includes everything you need to perform 30 tests: a low-range round comparator, refill, activator solution, 25 mL sample cup, and step-by-step instructions.

Why You’ll Love It

- Portable and complete: comes with everything you need in one case, ready to take into the field.

- Quick and reliable results: uses the proven DPD method for free and total chlorine.

- Affordable option: same trusted CHEMetrics accuracy as the K-2504, but streamlined for low-range use only.

- Designed for low-range testing: Built specifically for measuring chlorine in the 0.1–2 ppm range, so you don’t pay to test levels you don’t need.

- Simple workflow: No complicated steps or extra tools, just a clear, streamlined process anyone can follow.

Who It’s For

The K-2500 is ideal for anyone who works with water systems where chlorine levels are typically low, including:

- Municipal water utilities

- Drinking water treatment plants

- Pools and spas

- Breweries

- Food and beverage processing facilities

- Cooling towers

- Pharmaceuticals

- Potable water

If maintaining safe, compliant, and high-quality water is part of your job, this kit gives you an easy way to check chlorine levels on-site with confidence.

CHEMetrics K-2500: Affordable. Accurate. Easy.

Wastewater is any water that has been used for a process and can no longer be used. This can range from domestic processes like washing your hands to industrial processes like manufacturing chemicals. These processes leave contaminants in the water like detergents, chemicals, food, and of course body waste. Municipal wastewater refers to wastewater from an entire community that is gathered together through sewers at a wastewater treatment plant (WWTP). To prevent harm to the environment and public health, this wastewater is treated by various methods and then discharged into local bodies of water. This article will provide some basic information on municipal wastewater like why it is important, how it works, and how AquaPhoenix Scientific supports wastewater management.

What Is Municipal Wastewater Treatment?

Before wastewater is treated, it has to be collected. Most sewage is gathered in a community’s sanitary sewer that traffics the waste to the treatment plant. Sanitary sewers are distinct from stormwater sewers, which take runoff from storms and release it into a natural body of water. Some communities combine the two, but modern sewage structures have moved away from this practice. Once the sewage arrives at the treatment facility, which is now called influent, it begins to be treated.

Wastewater treatment is the process of removing debris and contaminants from the influent. Wastewater treatment is commonly split between Municipal and Industrial. Both have the same common goal of creating cleaner water, but they differ in a few key ways. Industrial wastewater treatment typically refers to the on-site treatments a business does to wastewater before releasing it. Where municipal wastewater is an aggregate of waste from an entire community, industrial wastewater usually has waste from one facility or group of facilities, leading to their wastewater being more regular. Industrial wastewater commonly has harsher or more concentrated contaminants, whereas municipal wastewater is less concentrated, but the contaminants, concentration, and volume of wastewater are less predictable. This lack of predictability requires municipal wastewater treatment to accommodate the needs of its influent.

Municipal wastewater treatment is typically done in three stages: primary, secondary, and tertiary. The goal of the treatment is to turn the wastewater into cleaner water that can be discharged back into the environment.

What Are the Objectives of Municipal Wastewater Treatment?

Before wastewater treatment, water was used and then dumped onto the ground or allowed to flow back into the local lakes or rivers. The only treatment the wastewater received was from natural processes. Dilution, filtration through rocks and soils, and digestion by natural bacteria all removed impurities and contaminants but at a very slow rate. As human populations grew, the amount of wastewater outpaced the cleaning abilities of the natural systems, so freshwater quickly became contaminated. In order to preserve the environment and maintain healthy drinking water sources, wastewater treatment became a necessity.

A wastewater treatment plant’s goal is to create water with fewer contaminants that can be discharged into the environment without causing harm to the ecosystem or human health. In the United States, safe water is determined by the United States Environmental Protection Agency (USEPA), through National Pollutant Discharge Elimination System (NPDES) permits. These permits put limits on the contaminants and the concentrations that can be in the discharged water, called effluent. Common contaminants limited by NPDES permits include Total Suspended Solids (TSS), pH, Biochemical Oxygen Demand (BOD), ammonia, and more. These environmental regulations are critical as an excess of these contaminants can cause disease, algae blooms, death of local wildlife, or other harm to the local ecosystem.

From an economic perspective, the plant wants to remove impurities from the water in the most time and energy-efficient manner possible. For this reason, many WWTPs follow a similar structure for treatment with varying technologies and methods.

How Do Municipalities Treat Wastewater?

Most municipalities treat their wastewater in three steps called primary, secondary, and tertiary steps. Each plant will be unique with their challenges and the order of treatment could be shuffled around and technologies may be different, but plants generally follow these steps.

The primary treatment is the removal of solids from the wastewater. This is done by using screens of closely spaced bars and settling tanks. The screens remove large pieces of debris like trash or rags. These screens are periodically cleaned to remove the debris and is disposed of by burial or landfill. This is in part, is why flushing thick wipes is harmful to sewage systems. Smaller particles like sand and silt are removed in grit chambers which are longer tanks that slow down the flow so it settles out. Finally, suspended solids are removed in large sedimentation tanks. The water sits in these tanks while the solids settle out creating a sludge. Mechanical scrapers remove the sludge at the bottom and scrapers above remove grease and other contaminants that float. Primary treatment removes roughly 60% of total suspended solids (TSS) and roughly 35% of Biochemical Oxygen Demand (BOD).

Secondary water treatment focuses on the removal of soluble organic matter that escapes the primary treatment. This step typically features a biological process where microorganisms are used to consume the contaminants and convert them into harmless byproducts like carbon dioxide and water. Treatment with bacteria can be accomplished in a few ways, but two of the more common are activated sludge and trickling filter methods. Activated sludge is a common method, where sewage is mixed with activated sludge and aerated so the bacteria thrive. Another common method is a trickling filter, where sewage is sprayed on a bed of stones filled with the microbes. As the sewage trickles through, the bacteria digests the contaminants. In both cases a clarifier is used after to allow the denser material to settle out.

Tertiary treatment is the final step of treatment and it focuses on contaminants that are not biodegradable or the remnants of the other treatment steps. This step often utilizes granular filters for treatment and chemical treatments to remove excess phosphates, ammonia, nitrates, and more. The tertiary step will vary significantly depending on the water reclamation facility.

After all these steps, the water can then enter the environment safely

Wastewater treatment is an intense process that must work efficiently in order for us to have safe and healthy communities. With removing solid matter, then soluble organic material, and finally removing chemical contaminants, there are a lot of treatment processes to maintain and optimize. AquaPhoenix offers products to help keep water reclamation facilities efficient. We offer reagents, chemicals, test kits, pumps, panels, and data management software. Whether you need a few items to get through the week or want to set up a regular order of bulk reagents, we can meet your needs at www.labnw.com